Recovery of iridium from anodes containing iridium and titanium

In modern industry, iridium and titanium are widely used in various high-end technology fields, especially in electrochemistry and metallurgy. With the rapid development of industry, the use of iridium-titanium anodes has become more and more common, which has also brought about a new problem-how to effectively recover the iridium in iridium-titanium anodes. This article will explore in depth the process, significance, and environmental and economic value of recovering iridium in iridium-titanium anodes.

What is iridium titanium anode?

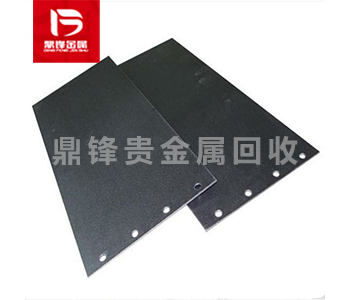

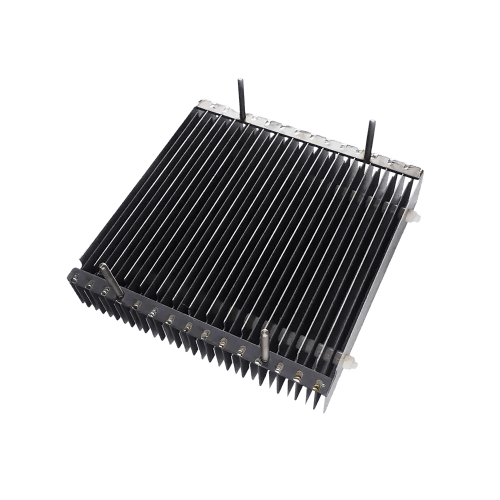

Iridium titanium anode is an anode material made of titanium alloy and iridium, which is commonly used in electrolysis, corrosion protection, electrochemical reaction and other fields. Titanium itself is a very corrosion-resistant metal with strong antioxidant ability, while iridium, as a precious metal, has excellent electrochemical properties, which can effectively improve the durability and efficiency of the anode.

Iridium titanium anode is commonly used in industrial electrolytic cells, such as water electrolysis, chlor-alkali electrolysis, metal smelting and other processes, especially when working in some high temperature and high corrosion environments. The performance of iridium titanium anode is particularly outstanding. These anodes usually have a long service life, but over time, the anode surface will gradually wear and damage, resulting in the loss of iridium. Therefore, how to recycle the iridium in it has become a crucial issue.

Iridium recovery process in iridium-titanium anode

The recovery of iridium in iridium-titanium anode involves multiple links, from the disassembly of the anode, the extraction of iridium to reuse, each link requires professional technology and equipment. The following are the basic steps for the recovery of iridium in iridium-titanium anode:

1. Disassembly of iridium-titanium anode: The recovery of iridium-titanium anode first requires the anode to be removed from the electrolytic cell. Since iridium-titanium anode usually exists in the form of alloy, which means that it is closely combined with titanium, it is necessary to separate the iridium-titanium anode from other metal parts through appropriate disassembly technology. The disassembly process requires the use of special equipment to ensure that the structure of iridium is not damaged during disassembly.

2. Removal of titanium material: The core component of iridium-titanium anode is titanium, while the content of iridium is relatively low. In the recycling process, the titanium part of the anode needs to be removed first. Common methods for removing titanium include acid leaching and electrochemical separation. Through these methods, titanium metal can be effectively removed, laying the foundation for the next step of iridium extraction.

3. Extraction of iridium: Extraction of iridium is the most critical step in the iridium recovery process. Since iridium is chemically very stable, it is usually difficult to dissolve directly in traditional chemical methods. In order to extract iridium, the iridium chloride method or the iridium sulfate method is usually used. Through these chemical reactions, iridium can be separated from the alloy, and finally a higher purity iridium metal is obtained.

4. Purification of iridium: The recovered iridium usually needs to be further purified. Since the purity of iridium in iridium-titanium anodes is often not high, the purity of iridium can be improved through refining processes to meet the standards for industrial use. During the purification process, chlorination, solvent extraction and other methods are often used to remove impurities to ensure that the quality of the final iridium metal meets the requirements.

5. Reuse: The purified iridium can be put into use again to make new iridium-titanium anodes, or used in other high-tech fields. For example, iridium is widely used in electronics, aerospace, medicine and other fields, especially in high temperature environments. Therefore, recycling iridium can not only provide important metal resources for industry, but also effectively reduce dependence on natural resources.

Environmental protection and economic value of recycling iridium

Environmental value: Iridium is a rare and valuable precious metal. With the gradual reduction of global iridium resources, recycling iridium is particularly important. By recycling iridium in iridium-titanium anodes, the mining of iridium ore can be effectively reduced and resource waste can be reduced. The iridium recycling process is more environmentally friendly than mining new iridium ore. It not only reduces the damage to the environment caused by ore mining, but also effectively reduces the emission of waste gas and wastewater generated during the production process.

Iridium recycling can also reduce the accumulation of waste such as iridium-titanium anodes and prevent them from polluting the environment. If the waste of iridium-titanium anodes is not treated, it may cause potential harm to soil and water sources. Therefore, by recycling iridium, the utilization rate of resources can be improved while protecting the environment.

Economic value: Iridium is an expensive precious metal with large price fluctuations, so recycling iridium has great economic potential. With the increase in demand for iridium, the market price of iridium is also rising. By recycling iridium in iridium-titanium anodes, not only can the production cost of iridium be reduced, but also considerable economic benefits can be brought to enterprises.

In the recycling process of iridium-titanium anodes, due to the high recovery rate of iridium, a large amount of iridium can be extracted from the discarded anodes, which provides a continuous supply of high-quality raw materials for the metallurgical and electronic industries. At the same time, iridium recycling can also promote the development of related industries, promote the development of the circular economy, and achieve sustainable utilization of resources.