Iridium Recycling Guide

Importance of Iridium

Due to the scarcity of iridium, recycling iridium has become an important means of resource utilization. This article will introduce the recycling and purification process of iridium in detail to help everyone better understand how this process promotes resource recycling and environmental protection.

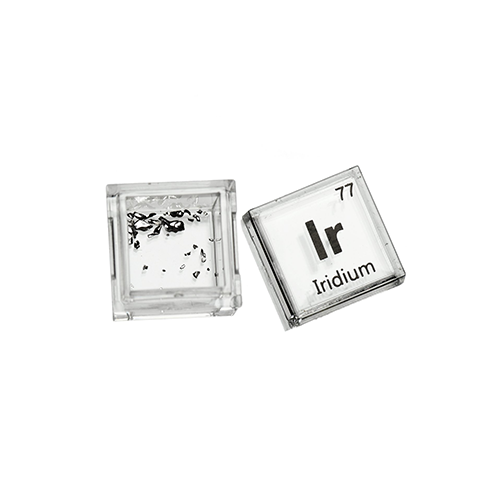

Properties and Applications of Iridium

Iridium is an extremely rare metal and a member of the platinum group metals. It has high density, high hardness, and excellent corrosion resistance, which enables it to work stably in extreme environments. Iridium is mainly used to manufacture high-end equipment such as spark plugs, sensors, catalysts, and electronic components. The application of iridium is crucial in aerospace, automotive industry, petrochemical industry and other fields. Due to the scarcity and high market price of iridium, the demand for recycling and purification of iridium is gradually increasing.

Iridium Recycling Channels

Iridium recycling usually comes from two main areas: industrial waste and electronic waste.

Industrial waste: In some high-precision manufacturing processes, iridium is used to produce catalysts or other alloy materials. These processes may produce iridium-containing waste, such as iridium-containing metal chips or discarded iridium catalysts. When dealing with these wastes, companies can reduce the consumption of raw materials by recycling iridium.

Electronic waste: With the advancement of technology, iridium is used in more and more electronic devices. Especially in the fields of high-end electronic components such as spark plugs and sensors, the demand for iridium is increasing year by year. Many waste electronic devices, such as automobile ignition systems and electronic components, may contain a certain amount of iridium. When these electronic devices are eliminated or scrapped, the iridium in them can be extracted through professional recycling processes.

Catalyst recycling: Iridium is widely used in industries such as petroleum refining and chemical synthesis as an important catalyst. These catalysts lose their activity after a period of use and need to be replaced. During the replacement process, these old catalysts contain a large amount of iridium, so recycling old catalysts has become an important way to recycle iridium.

Iridium recycling methods

Iridium recycling methods are relatively complex and are mainly divided into three types: mechanical recycling, chemical recycling and electrolytic recycling.

Mechanical recycling: Mechanical recycling refers to the separation of iridium-containing waste materials by physical methods such as crushing and screening. This method is suitable for the recycling of some metal waste materials, but due to the strong viscosity of iridium, the efficiency of mechanical recycling is low, and it usually needs to be used in conjunction with other recycling methods.

Chemical recycling: Chemical recycling methods mainly extract iridium from waste materials through chemical reactions such as dissolution and precipitation. Common chemical recycling methods include using strong acids such as aqua regia (a mixture of concentrated hydrochloric acid and concentrated nitric acid) to dissolve iridium, and then separating iridium from the solution by selective precipitation. This process needs to be carried out under precise chemical control to ensure high-purity recovery of iridium.

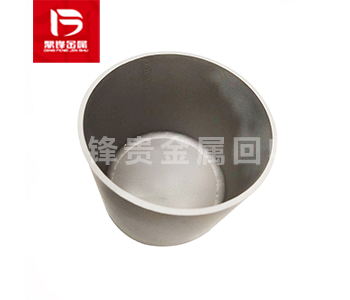

Electrolytic recycling: Electrolytic recycling is to extract iridium from waste materials through an electrolytic process. This method is suitable for waste materials with high iridium content, such as iridium-containing alloy materials. By dissolving the waste in an electrolyte, iridium ions are deposited on the electrode when current passes through the solution, thereby achieving iridium recovery.

Iridium purification process

The purification process of iridium is mainly completed by a combination of chemical and physical methods. Because iridium usually coexists with other precious metals (such as platinum, palladium, etc.), the purification process requires high-precision and high-cost technology.

Solvent extraction: This method uses different solvents to dissolve iridium and other impurity metals, and uses their different solubility differences in solvents to separate iridium. Solvent extraction is often used for large-scale iridium purification, and can efficiently extract iridium from other metals.

Ion exchange method: Ion exchange is a method of purifying iridium by using solid resin to exchange metal ions in solution. In the recovery process of iridium, ion exchange resin is used to adsorb iridium ions in solution, and then iridium is eluted from the resin by eluent. This method is easy to operate and can obtain a higher purity of iridium.

Chlorination method: Chlorination method generates iridium chloride (such as IrCl₃) by reacting iridium with chlorine, and then converting the chloride into iridium metal by reduction reaction. This method is often used for high-purity production of iridium and can effectively remove impurities.

Melting method: At high temperatures, the melting points of iridium and other impurity metals are quite different, and iridium can be purified by melting separation. This method is mainly suitable for the purification of iridium-containing alloys. Through smelting, iridium will be separated from other metals to form iridium with higher purity.

Challenges and prospects of iridium recycling

Although the recycling technology of iridium is relatively mature, it still faces many challenges due to factors such as uneven distribution of iridium and low iridium content in waste. The purification process of iridium is time-consuming and costly, so there is still a certain economic pressure in large-scale recycling.

With the continuous advancement of recycling technology and the emphasis on rare resources, the prospects for iridium recycling and reuse are very broad. In the future, with the continuous breakthrough of technology, the efficiency of iridium recycling is expected to increase, thereby reducing the production cost of iridium and promoting its application in more fields.